IRS

Introduction

The product

The Jorge Tadeo Lozano university has created a research group from the cooperation between the engineering and design departments whose primary purpose is to explore the technology related to urban mobility.

E-Tadeo is a mobile laboratory in which multiple technologies will converge to recreate experiments related to motion and interactions.

Considering the university's outdoor/indoor spaces are the primary playground of the mobile laboratory, the scale, speed ranges, and maneuverability define the main challenges of this initial stage.

The Problem

Technology is constantly shaping the cities, and nowadays, digitalization, platforms, liveable cities concept, and the driverless cities goal bring hundreds of questions about the guidelines to define our immediate contexts.

Therefore, bringing the opportunity to explore and build visions about the future of mobility to the university represents a great chance to learn/teach and research relevant topics.

The goal

Our goal is to build a platform/robot/vehicle able to assist the development of experiments of students and researchers in the departments of engineering and design.

In essence, the researchers may generate add-ons for the technological package, and test multiple use alternatives through the modification of the bodywork.

E-Tadeo

Responsibilities

My background in mobility and design allowed me to support the research team in multiple activities.

I initially participated in the formulation of the overall research project through approaches proposals, presentations to stakeholders, and meetings with research leaders from different departments.

Additionally, I have participated actively in the prototypes' design and development, from volumetric mock-ups to the refinement of the final samples.

Additionally, I have participated in activities with students and talks organized by the university about the future of mobility.

Defining scale

Wood & Cardboard

Although we calculated general dimensions for the product, as a team, we decided to build a wood & cardboard prototype to have a better perception of the volume in different contexts.

Such exploration allowed us to move the mock-up around multiple places gaining insights into the motion and dimensional requirements/challenges.

We adjusted the bounding box and construction details for the CAD data through the collected information. In addition, we worked with existing components to refine the spacing and distribution of the final frame.

On the other hand, having a 1:1 scale model allows us to sketch (tapes and post-its) on the cardboard surfaces and explore shape, positioning, and overall perception for future bodyworks and design and interaction experiments.

Stage 1

Photo By Prof. Abel Rodriguez.

Size & Context

Understanding the vehicle's actual size and the challenges behind real obstacles and interactions such a product may encounter during its journeys brought interesting insights that helped us evaluate the acquisition of components for the final prototype.

Exploring CAD

3D Printing

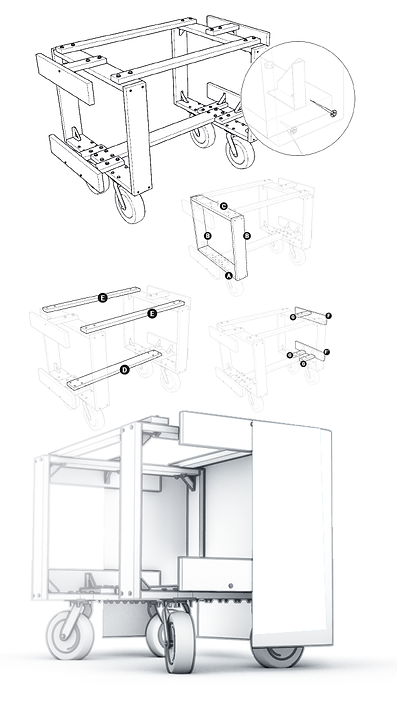

The refinement of CAD models gave us the guidelines for developing the frame v1.0 and evaluating the assembly of components ( directional motors, propulsion motors, batteries...).

On the other hand, to better understand the bodywork surfaces and create material for support design workshops with the students, we printed a 1:5 scale model.

Such a model allowed us to reflect on the definitive prototype's assembly points and production processes and provided constraints for the ideation process of the students working on bodyworks proposals.

We 3d-printed parts for the validation of two different frames proposals.

Additionally, we printed each piece of the bodywork and generated a CNC mold for thermoforming the windshields in polycarbonate.

Stage 2

Photo By Prof. Abel Rodriguez.

3D components.

3D printing allowed us to create small models and recreate components for precise constructions elements like joints.

Prototype

Under Construction

Frame, Plastics & algorithms

Having an advanced stage in terms of digital prototypes enables us as a team to build metal framing and experiment with fiberglass to get closer to the physical version of the prototype.

On the other hand, understanding the physical challenges (motion, mass, size, and context features) allows the engineering department to set the technological package and define its coding.

Work in progress.

Stage 3

What I learned

This approach to academic research allowed me to understand the design process from a new perspective. The goals go beyond the market because the main guidelines are related to exploring methodologies and creating tools to support learning.

Needless to say that the interaction with students is constantly bringing a fantastic sense of curiosity that pushes forward any creative venture.